An alternate study to meet the LCA Mk.1A/Mk2 requirement. One of the great lacunae in planning of our weapons programmes is the lack of alternative studies. Even in tightly state controlled economies competitive proposals are mandatory. It is economical in every sense to have competition.

The LCA Mk1a /Mk2 are engineering effort wise new proposals. The prototypes are expected circa 2025. We have no back ups for this class of aircraft. The Bisons will have gone.

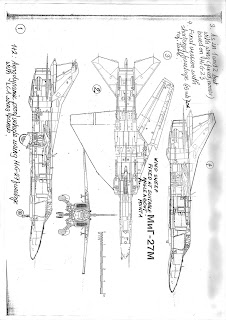

It seems that the fuselage of the MiG 27 combined with a new fixed wing - a 45 degree based on the existing wing or one based on the LCA's wing plus a tail could be copied much faster.and could meet all the problems- lack of real estate, gun firing,etc reported in the CAG report.

At least a preliminary study is mandatory! It should cost no more than a crore and six months.

The LCA Mk1a /Mk2 are engineering effort wise new proposals. The prototypes are expected circa 2025. We have no back ups for this class of aircraft. The Bisons will have gone.

It seems that the fuselage of the MiG 27 combined with a new fixed wing - a 45 degree based on the existing wing or one based on the LCA's wing plus a tail could be copied much faster.and could meet all the problems- lack of real estate, gun firing,etc reported in the CAG report.

At least a preliminary study is mandatory! It should cost no more than a crore and six months.

A proposal to study

the MiG23/27 air frame with the GE F414 engine

As a backup for

the LCA Mk1A and the Mk 2 programmes.

Prodyut Kumar

Das

Designer/

Engineer

Professor IITK etc. (retd.) Kolkata,

27 February 2019

TABLE OF

CONTENTS pp.

1.

SYNOPSIS 3

2.

THE NEED FOR THE

STUDY 4

3.

THE ADVANTAGES

OF USING A BASE A/C 4

4.

THE MIG 23/27 AS

A BASE 4

5.

BACKGROUND

TECH.NOTES MIG 23/27 5

6.

THE DEVELOPMENT

STRATEGY 6

7.

THE ENGINEERING

CHANGES 6

8.

THE LIMITS OF

THE STUDY 8

9.

OTHER PROJECT

STUDIES 9

10. ESTIMATED MANPOWER 9

11. CONCLUSIONS 10

12. A TABLE OF COMPARISONS 10

13. SIDE VIEWS 11

SYNOPSIS

The

IAF is today in a critical situation in relation to the LCA category of aircraft.

This has happened because of past lacunae in organization and management of the

LCA programme. We have to consider what would have been our situation today had

we in 1989 when the review had shown that the proposed LCA was not going to meet

specifications, we had alternative projects studies to fall back on.

What the impact of such precautions may have had on the situation today needs

no elaboration

The LCA Mk1 does not meet specifications. The

PAC 2153/ CAG report 114 indicate that the airframe is deficient in performance

and expandability. The extent of re-engineering on the airframe is around 40% for the airframe alone. The

configuration is difficult to develop. The amount of work to transform the Mk1 to

the Mk.1A is at least as much as was required to transform the Mirage III into

the Mirage 2000. The seasoned, well organized French took four years to get the

Mirage 2000 into IOC.

The

Mk2 is almost a new aircraft with attendant risks. India must have viable

alternatives rather than rely on “Hope” when 2023 comes. There is a strong need

as of the present for a “what if –in case” study of meeting the

LCA Mk2 specifications based on the proven MiG23/27 along with several similar such studies. Such back up studies are standard practice in most aircraft programmes

and should have been done ab initio at the launch of the LCA programme.

This

proposed project is to study if a structural surgery of the MiG 23/27 series

aircraft.

Structural

surgery is the next evolutionary step to the upgrade programmes carried out on

the Jaguar, MiG 21 and the MiG 23 aircraft and about which the IAF has

commendable experience. In the upgrades

programme the systems have to be upgraded within the constraints of “not

touching the airframe”.

In structural surgery

(see

Indian Defence Review paper II/1990 pp.110-119 by the present author) the airframe is also modified to evolve

a new and more suitable aircraft. The MiG 27 itself is an example of structural

surgery on the basic MiG 23 aircraft with changes to the nose, cockpit,

intakes, wheels and afterburner to make the aircraft suitable for close support

duties. The Israeli Kfir is another example.

Since

modern engines and avionics are more compact, lighter and superior in

performance to those of the MiG 23 vintage the advances in performances seen in

Upgrades are further enhanced and optimized by the structural modification of a

basic airframe. It is possible to evolve a design that will not only meet the

Tejas Mk2 requirements it will be a more certain to achieve its time targets

thanks to a more certain “base” i.e. the MiG 23/27 aircraft. The comparative

figures are on page 10.

A

provisional funding of Rs. 5 crores for the project study and a time scale of 6

to 8 months should be sufficient. If it cannot be done in that time it will

never be done. Te sum of money is affordable but potential in terms of time

saving and “pacing” the LCA project, and the knowledge gained is incalculable.

THE NEED FOR THE

STUDY

The

Tejas programme continues to be uncertain. This is reflected in the recent CAG

report. In summary:

i)

The

airframe is significantly overweight. It so happens that the configuration is

particularly weight sensitive.

ii)

It

will not achieve its range payload specifications.

iii)

The

design still needs considerable refinement and cleaning up. It will not meet

its energy related performance specifications.

iv)

The

airframe is too small to house all the equipment now desired.

The

configuration of the aircraft- tailless delta with FBW results in any change leads

to a cascade of changes. Whilst technically there are no big challenges in

doing all of the above these changes have not happened 18 years after first

flight.

To

base the successor design LCA MK2 on a somewhat “kuchha” base of the LCA Mk.1 as

it exists at present without having a

back up may lead to a repetition of what has happened previously. The strongest

reason is the poor delivery on promises by the concerned organizations which

now has to be planned for.

THE ADVANTAGES

OF USING A BASIS AIRCRAFT

1)

CFD

and wind tunnel studies are useful for comparison but less accurate and

reliable in absolute terms. This is eliminated as the basis aircraft acts as a

full scale wind tunnel model and also can be instrumented to generate needed

data.

2)

Less

experienced design teams may find it difficult to design a service friendly

aircraft. The use of an existing design gives a readymade list of features to

be retained or need to be improved.

3)

Advances

in technology over the design era- sixty years in the case of the MiG 23/27

means significant and guaranteed improvements in utility can be achieved –even

in a “ditto” or “Chinese” copy. The CPAFAF‘s TU-16/H5 is a case to the point.

4)

Very

large efforts required to perfect handling, cockpit ergonomics, safety and

Weapons delivery and gun firing which may require an additional thousand

sorties are reduced to a fraction.

5)

There

are psychological resistances during the certification process. The

availability of proven structures and systems speeds up the process and these

are considerable.

The

intelligent designer can slash the work load by 50 to 70%.

THE MiG23/27 AS

A BASIS FOR THE LCA MK.2 SPECIFICATIONS.

i)

The

MiG 23 was the original BVR fighter. Its airframe performance equals or exceeds

those required LCA Mk.2 specifications.

ii)

The

aircraft was in prolonged IAF service and used in combat. Its advantages and

shortcomings are well known to the customer. The exact areas of improvements

are in sharp focus.

iii)

Much

of the documentation and airframes are available as is the human knowledge of

the operators. This information will cut down the need for repetitive trials in

many significant areas- air brake location on the fuselage or gun firing trials

for example. Detail design problems are under emphasized in India and are more

time consuming than aerodynamic problems and make the difference between a

disliked aircraft and a well loved one.

iv)

“De-tuning” the

design from a Mach 2.3 to Mach 1.6 will easier than refining

the LCA in terms of the speed.

v)

The basic MiG 23/27 airframe is amenable to

development. Being a conventional layout there will be less “cascade” or

“linked” changes. For example if the FBW is not cleared for flight to match the

flight programme the configuration can be be re-arranged as a conventionally

stable aircraft until the problem is sorted out. This is not possible in the

LCA. The proposed canards for the LCA Mk2 will also require considerable

refining lest the traps in the canard

layout-fore plane/main wing interference for example or the higher induced drag

of the low AR fore plane is not fallen into.

vi)

The reduction of the Mach 2.3 speed to Mach 1.6

means that the 72 o wing sweep and indeed the VG requirement can be totally

eliminated. There were Russian proposal to such effect but at that time the

Mach 2.3 top speed was considered sacrosanct so a VG was essential.

THE MiG 23/27:

Some background technical notes.

Why the MiG 23

needed VG.

The

MiG 23/27 was designed in the 1960s and the VVS’s requirements were:

i)

A

top speed of Mach 2.3 at 12,000 mts

ii)

Comprehensive

BVR and IRST capability along with CCM capability.

iii)

Ability

to operate from Soviet Warpac rough fields. The last was not an IAF

requirement.

The

Russians experimented with lift engines and variable geometry (VG) before

choosing the then fashionable VG configuration with outboard hinge and three positions

manually selected swept wing. The heavy weight and the size of the Russian

Saphir 23 radar and the Mach 2.3 top speed needed a heavy and powerful engine

and its consequent load of fuel. This enforced the use of the VG to keep the

landing speed within reasonable limits despite its obvious penalties including around

400kgs extra weight i.e. 4% of the empty weight.

The

reduction in top speed to Mach 1.6 means less required power and hence the size

and weight of the engines. The modern ELTA radar preferred by the customer is

both lighter and requires less base power. 1960s Soviet technology accessories-

hydraulics, electrical and avionics were both heavy and bulky and can be

replaced by lighter modern systems. The same applies for materials including

brake materials. All these result in an inward weight spiral so that the

specifications can be met by a “cut down and squeezed” MiG 23/27 which no

longer requires a VG wing to have an acceptable field performance. The downward

weight spiral estimate is given in the Engineering Changes.

THE DEVELOPMENT

STRATEGY

As

detailed below the direct weight savings

due to replacement of the wing sweep mechanism, the engine and radar will

amount to a weight savings of 1500 kilogrammes. The consequent “cascade”

changes will result in a total weight saving of 2000 kilos.

Since

the top speed of Mach 2.3 is no longer required the max.wing sweep of 72

degrees and the extra engine power will be eliminated and the Mach 1.6 speed of

the specification can be met by a simple fixed wing based on the existing

design but with greater emphasis on leading edge flaps to retain the airfield

performance. No composites will be used

in the prototypes as this militates against the rapid modifications that

are needed

THE ENGINEERING

CHANGES

The

engineering changes vis a vis the Mig 23 will be as listed below.

1.

Radome

The radome contours will be based on the MiG 23

suitably modified for the ELTA 1M 2032. The radome is expected to be somewhat

smaller than the SAPHIR 23 base radome saving weight and drag.

2.

Cockpit

The armoured cockpit of the MiG 27 will be retained.

The Glass cockpit technology already developed for the upgrades will be used. Rear view can be improved via sensor fusion

and MFDs. The ejection seat will be replaced by a modern seat.

3.

Intake

Given the lower power of the GEW 414 or similar

engine vis a vis the R 29B the variable intake of the MiG 23 BN will be

retained as opposed to the fixed intake of the Tejas or the MiG 27 at least in the demonstrator aircraft.

4.

Mid Fuselage

the customer

will have two options:

i)

Keeping

the existing MiG 27 fuselage cross section and use the space for equipment and

extra fuel

ii)

“Squeezing”

the fuselage to closely wrap around the F414 which is 103 mm smaller in

diameter. This will reduce the transonic cross section and help improve drag, transonic

acceleration and energy related performance as also further weight reductions

but reduce the radius of action compared to i) above.

5.

Deletion of VG

and lowering of wing datum

i) As already indicated the VG feature is no longer strictly

necessary and the wing will be replaced by a wing of similar area and aerofoil

section but with the sweep fixed at approximately 45 degrees. The LE flaps will

be improved and made full span the technology developed for the LCA. A study

will also be made to compare the performance with the wing using the Sukhoi Su

7 aerofoil section which was noted for its excellent handling in combat speeds.

ii) If roll coupling problems have been

reported it may be possible to improve this by lowering the wing datum by the 53

mm vis a vis the centre line of the fuselage. Coupled with the lighter engine

the handling of the aircraft in rolling will improve.

The elimination of the extreme sweep of

72 degrees will give a bonus in that the Aerodynamic centre (AC) will shift

back much less. Consequent to the reduction in the AC movement the “tail

volume” will be reduced Hence the rear fuselage aft of the Cg will be reduced

in length by about 1 metre saving weight and drag.

6.

Elimination of

folding underfin

It is expected that the fin and the tail plane will

be reduced in size and it is quite possible that the folding under fin can be replaced

by a smaller fixed under fin/eliminated with saving in weight and drag.

7.

Relocation of

pylons for better optimization

To avoid the usage of variable sweep pylons as in

the American F 111A the Russians elected to put all the pylons in the wing

glove. This was sub optimal as the forward cg meant a larger than necessary

tail empennage as well as a heavier nose under carriage. With a fixed sweep

wing it will be possible to relocate some of the pylons out on the wing thus

relieving wing bending moments as well as allowing the missile sensors a

greater field of view. The weight of the nose undercarriage can be reduced.

8.

Smaller engine

inlets

The smaller mass flow of the GE engine 86 kg/sec vs

105 kg/sec means that the intakes will be smaller. This will result in weight

and transonic drag reduction whilst the greater L/D ratio of the intake duct

means that better “surge resistance” can be expected during gun firing.

Alternately if the fuselage cross section is kept

same as the present (p.6 pt.4) an additional 550 lits of fuel can be stored.

9.

Deletion of JATO Pylons

The MiG 23/27 was equipped with JATO pylons to meet

rough field operations. If these are not a part of the doctrine these pylons

will be eliminated saving weight and drag.

10. Artificial Intelligence

AI will be introduced into the aircraft to improve

serviceability as well as give a pilot reminder and warning aural messages.

Depending on the advantages of each incremental surgery the changes have to be

menu-ed against time and organized into a minimum list and subsequent changes

can be introduced as per production block. The LCA Mk1 software already

developed can be incorporated.

Weight Savings

The

MiG 23 aircraft was designed using the technology of 60 years go. Improvements

in technology since then has resulted a possibility of considerable savings

which could radicalize the concept of the aircraft.

Direct savings.

Feature changed Weight Weight

saved

Elimination of the VG mechanism 400

kgs.

(Estimated from Soviet sources)

Replacement of engine R29B by F 414

Weight of Tumanskii R29B 1830kgs

Weight of GE 414 1130

kgs 700kgs

Replacement of Radar

Weight of

Saphir 23 385

kgs

Weight of Elta 1M2032 100kgs 285 kgs

Total direct

weight saved 1380

kgs

The direct savings will lead to further indirect

savings due to aerodynamic and structural reasons. These are:

1.

Reduction

in fuselage lengths approx 1mts as AC

movement is reduced 100kgs

2.

Deletion

of folding ventral fin 85

kilos

3.

Reduction

due to ducting cabling wiring pipeline etc 100

kilos

due

to 1 above

4.

Reduction

in tailplane area due to lower a.c. shift 50

kilos.

5.

Due

to replacement of Soviet era connectors 60

kilos

6.

Due

to lighter wheel and brakes of modern technology 75 kilos.

7.

Due

to better location of pylons and deletion of RATO pylons 40 kilos

8.

Weight

improvement to the undercarriage 40

kilos

There

will be a significant saving in changing from Soviet era connectors and 28v

electrical systems to modern Western equipment and 115 v. constant frequency

systems as no doubt the Air Force is well experienced in.

Generally

a two ton (2000kgs) weight saving can be expected at this stage of estimation.

The prototype

aircraft can expect to be around 7500 kilos basic empty weight without using composites which can be

introduced only after the design is proven. Using

composites on the wing skins alone can save around 350 kilos above the given

figures and they should be introduced in the later blocks.

The Limits of

the study

To

serve its purpose such a study should be

severely limited and focussed scope to be achieved in a strictly defined time. The

study is a “what if we do this – what will we get “ confirmation of the above

idea and should not take more than 2 to 4 crores per study though no doubt people

can find means to overshoot the budget.

The

study should explore:

i)

Does

the MiG 23/27/F414 hybrid meet the MK2 specifications without any concessions?

ii)

The

extent of “stretch ability” of the design over the next two decades to

accommodate future growth. The layout will score heavily in this.

iii)

What

and where the information resources are available should the project go up to

the next stage.

iv)

The

cost estimates and timescales for an FSED and for the next step i.e. detail

design and mock up.

Scope of the

work

i)

Preparation of three project studies using the F414/

Eurojet/M88 and Russian engines and along with matching accessories. This is to

avoid commercial pressures which will be inevitable if the project is

attractive.

ii)

Performance studies based on comparative CFD and

wind tunnels studies. The availability of the MiG 23/27 will be particularly

valuable in underwriting the data.

iii)

Identification of resources required to build mock

ups and or prototypes and their availability in India.

Other

Project studies

There should be the following other

project studies either jointly with the original licensor or independently.

These should cover:

i)

Jaguar “big wing” with the

Maritime fuselage which was an original BAe programme in the 1980s.

ii)

The

HF 24 powered by the Honeywell F 125.

The airframe’s potential is unarguable and its known quirks can be tamed by

modern technology.

iii)

The

MiG 21 UPG/LCA systems packaged in

to a modified air frame based on the

Gnat much as the Orpheus powered Gnat was evolved from the Viper powered

Midge of one third the power of the Orpheus. The peculiarities of Military

marketing are such that people will listen to a “Combat Hawk” proposal but not

consider a superior solution in the Gnat re- surgery.

It

appears that the HF 24 drawings and documents have been destroyed. This

requires an investigation but the

absence of drawings does not stop the HF 24 from being considered as a base

for initial project studies. Modern e-engineering techniques such as laser

scanning and spectrography can regenerate all the data on the platform and the

rest of the study is no more than an upgrades programme. What will be needed

will be a one or two airframes in a reasonable state of preservation. The

technical history of the programme can be recreated given our great oral

traditions as exemplified by the Canberra reintroduction.

Intellectual

property Rights

issues may rise but since structural surgery with new equipment and systems the

resulting aircraft is essentially new and so IPR problems can be tackled. In

any case the vendors would be tackled by the prospects having lucrative markets

for the supply of the accessories and can be handled at the Government to

Government levels.

Estimated

Manpower

A

total of 10,000 to 15,000 man hours need to be budgeted for. Tentaitively the

need is for 6 engineers preferably with about ten years MiG 27 experience and

about 6 CAD/CAE engineers capable of working under guidance on modern CAE

software. Another two documentation staff would be indicated ,i.e. 15 engineers

working for six months.

Work location

Modern

communications makes the workplace location less important. Closeness to the customer to understand his

needs is the first requirement. The ideal at this (preliminary) stage would

be Air HQ as a project cell or IIT New Delhi. Admittedly IIT New Delhi does not

have an Aeronautical Department but it is overruled by the fact that the

project cell can be in almost daily interaction with the Customer and the

industrial back ground of NDLI can allow for small mock ups etc to be quickly

fabricated.

The

other location could be BRD 11 Nashik which would have the base aircraft at

hand. In the case of the Delhi location one CAT C sample of the airframe and as

much documentation as available will have to be located at the campus.

Conclusions

It

is common sense and standard practice that when unproven technological advances

are incorporated into a design to have not one but several plan Bs. These plan

Bs are carefully calibrated in terms of risks against an abscissa of time. Such

efforts are continued until the main project is reliably out of the woods.

Failure to do so has created the crisis.

Contrary

to the views broadcast bt the import lobbies the keeping of multiple projects

is not expensive. It would have cost us only 50 or 60 crores i.e. 10% of the

LCA budget of that time over perhaps six years to have funded any of the HF 24

based derivatives in 1983. The annual additional expenditure would have been in

the region of perhaps ten crores. The impact of having a HF 73/HF25 prototype

around 1989 does not need elaboration.

We

cannot correct the past. The present has to be seized. The LCA Mk2 as much as

the LCA mk.1A and the.AMCA must have at least shadow competitors at this

nascent stage.

Prodyut

Kumar Das

Engineer

.Professor (retd)

Kolkata

April 20 -2019

Sl.no.

|

Parameter

|

MiG 23/27

|

Redux

|

1.

|

Length

|

16.84

|

15.04

|

2

|

Span

|

13.995/7.779

|

10

|

3.

|

Height

|

5.145

|

5.145

|

4.

|

Wing

Area

|

37.27/34.16

|

34

|

3.

|

Empty

Weight

|

9595

kgs.

|

7500-7000

kgs.

|

4.

|

Clean

TO with 2 CCMs.

|

14,625

kgs.

|

12,625

kgs.

|

5.

|

MTO

|

18,570

kgs.

|

16,975.kgs.

|

6.

|

Internal

Fuel

|

4670kgs.

|

4670kgs.

|

7.

|

Fuel

Fraction

|

0.5586

|

0.80/0.5586

|

8.

|

Engine

Thrust

|

83.6/127

kN

|

57.8/98

kN

|

9.

|

Wing

Loading ( clean Combat)

|

430

kg/sq.mts.

|

371

kg./sq.mts.

|

10.

|

Power

Loading ( clean combat)

|

0.886

|

0.89

|

11.

|

Fixed

Weapon

|

6x30

GSh.

|

6x30GSh.

|

The three view drawing sshowing the MiG 27 fuselage with the LCA wing panels and one with a MiG 27 based wing at fixed sweep will be published in due course.

I agree Tejas should have been a competitive tender with HAL/ADA making one proposal and possibly the private sector making another proposal. The two proposals could've given birth to two prototypes to allow for a flyoff competition similar to how the US military runs their aviation procurement programs.At the moment HAL/ADA have a monopoly and as with any monopoly they are inefficient. But, I think suggesting the Mig-23/27 as the basis of a Modern fighter is a bit far fetched, the Mig-23 and 27 were quite capable fighters in their time but there airframes are part of a bygone era. Just look at the swing wing capability which doesn't have space on a modern battlefield, it is just dead weight and extra maintenance/lifetime costs. Instead of the Mig-23/27 a mirage 2000 would be a more accomodating basis for a teas Mk2 basis. In either case both the Russians nor the French would be very happy with Indian engineers reverse engineering their products. I would've thought a better solution would've been to buy the design work for a fighter like the IAI LAVI from the Israelis and bring it up to modern standards, essentially what the chineese did with the Chengdu J-10.

ReplyDeleteDear Sanku

DeleteI would think that both ( the MiG 27/IAI Lavi) are bad suggestions. But desperate situations call for do desperate measures. We need CERTAINITY in our defence programmes but that is not happening- almost as if by plan!

Have you thought what is obsolete in the MiG 27 fuselage? It is perfect for the LCA specns.I have NOT asked for the VG to be retained! You will save about 500 kilos and then some. If you read carefully -which you have NOT- you will see that I am calling for a MiG 27 fuselage -shortened somewhat- VG deleted and equipped with either the LCA wing or a fixed area fixed ( Non VG) mod of the MiG 27 fuselage but with teh MiG 27 empennage.. According to my study this will solve many of theconcessions being asked for.I amasking for a "What if we do this study". It wont cost the sky if you know what you are doing. We should not ignore the study.