A technology demonstrator for the

subsonic 5th Gen. AMCA Prof. Prodyut Kumar Das

The reader may find reading the earlier blog on Betaal and the specifications.c April 2023 on this blog relevant.

The idea

of a subsonic Fifth Generation AMCA is heretical but heretical ideas should be

discarded only after due diligence. The De Havilland Mosquito was initially discarded

for being a bomber without any defensive guns yet in service the RAF never had

as many as it could have liked partly because the experts had deemed that when

4-8 defensive guns were the norm a gun less bomber would not survive and so delayed support. A non-supersonic 5th

generation Combat aircraft may initially sound as unpromising as the concept of

the Mosquito.

Both the US and China have large subsonic bombers, the B 52 and the Ho-6. These are valued assets prized for their versatility and upgradability. Just how valued these platforms are can be gauged by the fact that the US is importing from the UK- something the Americans do but rarely- suitable RR 700 srs engines to repower these 70 yrs old warplanes. If this genre of aeroplanes is still relevant then by adding the feature of stealth, sensor fusion and AI weapons and starting ab initio we can have a potent addition to our air power. Using the advances in materials and propulsion technology in the past 70 yrs there can be a considerable reduction in size and weight of the aircraft since we do not need “global” capabilities and can accept a 1000/1200 n.m. combat radius – enough to cover IOR, Tibet /Sinkiang/ Kunming from standard Indian bases. sensor fusion and internal carriage of AI weapons they would be much more effective relevant

Perhaps the best endorsement for examining the "large capacity internal carriage of all weapons stealth" Betaal concept- is a remark I have re-phrased to capture the information about the F 35 deployed in Germany since the Ukraine conflict. “The F 35 can soak up huge amounts of information about EADs but it does not have the capacity to carry sufficient amounts of PGMs to take them all out”. The supersonic 5th gen has , in terms of Cessna Caravan operators, will, inevitably, weapons wise “cube out”.i.e. it cannot carry the requisite number of weapons even if the lifting capacity is there.

The next white hope offered by ADA- the AMCA- will not be happening any time soon. May be 2035 for a first flight and 2045 for an IOC 1 are my estimates if only because I feel that ADA needs a purge and reorganization if it is to perform even half decently. The IAF- if it still exists given the current rate of numerical decline- will be then facing a situation of fleet strength below recovery size i.e. even if then flooded with new equipment it will not have enough seasoned aircrews to handle the expansion. Blaming the Services confuse the issue. That there is an effective Import Lobby is no gainsaying but there has been rarely a case where an equal value product was ready on time and imports were nevertheless gone through with.

The Engineering realities to be considered are:

i) Avoid supersonic speeds as a special case. Designing

for even modest supersonic speeds < M 1.3 results in poor aerodynamic

efficiencies.

ii)

Statistically

that supersonic speed is rarely used, high T/W is.

iii)

The

installed power to disposable load of the aircraft increases by a factor of

almost three in case of supersonic a/c.

iv)

Stealth

by delaying detection and intervention is “quasi” performance. The introduction

of AI enabled “standoff weapons” has changed the concept of the Weapons

Platform to a Weapons Transporter. We are better off in Missile Technologies. Relatively low performance platforms, using AI

enabled weapons, can reduce the challenges of development of

Platforms/Transporters. A subsonic/transonic stealth platform is cheaper,

smaller and stealthier than a supersonic one in all respects.

With the

above development problems as reminders we have the Betaal questions.

Is

developing a matching 5th

generation fighter the most economical way of tackling the threat of marauding

F 35 s /J 20 s?

Has

other possibilities of countering the expeditionary F35s/J20s been explored? Going

by the symptoms displayed by ADA so far AMCA will not happen and an alternative

iron is needed in the fire. My prognosis is that the AMCA is going in for incorporating new technologies

without having developed the technologies i.e. stealth and data fusion to the

required level of expertise. What will happen is this: Thanks to somewhat better monitoring the AMCA

first flight, will be delayed by only a few years but there after the programme

will spin in to uncontrolled delay because ADA will repeat its struggle to develop

new technology on an operational prototype. It has neglected to think and develop

the technologies in the last two decades.. Failure, defined as a sustained

series of out of control delays, is guaranteed.

The IAF will be then facing a situation of fleet strength below recovery size i.e. even if then flooded with new equipment it will not have enough seasoned aircrews to handle the expansion. It took teh Israeli AF about 7 years to recover from the bashing the Egyptians gave it in 1973. For India the problem of finding sufficient crew material in abooming economy will be a challenge.

The options facing the IAF/ Defence Ministry today

is to plan for:

i)

Continued

further imports - which may have been the plan anyway! These s called development projects are mere

chaff & flare-ing and were meant to fail anyway!.

ii)

Continue

to hope that somehow the AMCA is just around the corner.

iii)

Reorganize

the chain of development

iv)

Examine

the subsonic 5th Generation Betaal AMCA

The subsonic 5th Gen. AMCA

An

alternate “Betaal” Subsonic 5th Gen. AMCA (ref 2) starts from the

premise that possibility of loss, even if it is “only” of "face", may deter aggression.

The threat of “flank attacks” somewhere" may deter aggression

elsewhere. Instead of tackling the F

35/J 20 s head on, the Betaal is a Flank attacker, a long range intruder that can attack targets in

the Tibet Autonomous Region and dominate the IOR from the Gulf to the Straits

of Malacca and, with “a nod and a wink” arrangement with Thailand, into the

South China Seas.

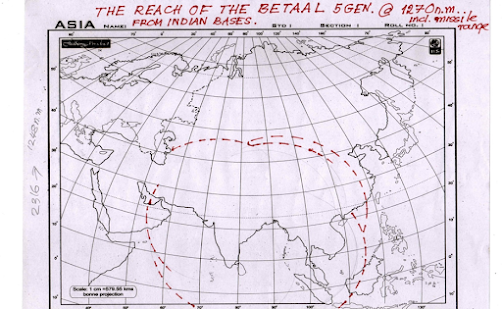

Reach of Betaal AMCA from Indian bases with combat radius of 1270 n.m with usual reserves.

The possession of this capability by the Indian Forces may cause a hesitation among rivals to change ground realities unilaterally. It is a subsonic long range stealth intruder with the internal i.e. “stealth” weapons capacity of a B 52.

It is a new

concept. The term “Long range” is relative. A radius of action of 2400

kms including the reach of the missile in a hi-lo-lo hi profile with a nominal

“10 ton” war load and a versatile weapons/equipment bay is the starting point

of discussions. Note that the design of the Bomb bay size and the radius of

action is surprisingly challenging to engineer & perhaps the core of the

project. Bombing up, un-loading, target acquisition, weapons release,

maintaining of stealth and a hundred little details are involved and will affect

the design overall. Some preliminary scantlings of the proposed Intruder are

set at Table 1 comparing the aircraft with the B 52.

Table 1. Dimensions are in MKS unless

stated.

|

Sl.

No |

Parameter |

B

52 H |

Betal |

Betal

Tech. Demonstrator |

|

1 |

Wing Span |

55.4 |

21.2 |

15.7 |

|

2 |

Length |

48.4 |

23 |

14.7 |

|

3 |

Height |

12.4 |

7.8 |

3.5 |

|

4 |

Wing Area |

370 |

142 |

55.0 |

|

5 |

Weapons Bay ( LxBxH) |

7.8 x 2.8 x 1.5 |

7.8 x 2. 8 x 1.5 |

6.0 x 1.7 x 0.8 |

|

6 |

Empty Weight |

83,100 |

31,125 |

6700 |

|

7 |

Clean /Stealth

Loaded |

123,000 |

49,780 Stealth |

13,900 Stealth |

|

8 |

MTO |

216,000 |

81,000 |

18,000 |

|

9 |

Installed Power |

8x 78kN |

3x83 kN |

2x15kN+1x30kN |

|

10 |

Cruise Speed (

kts/kmph.) |

445 kts/ 800 km |

500kts /890 |

450/810 |

|

11 |

Unrefuelled

Radius of action |

|

1300n.m |

1000n.m |

Various configurations and shapes cab be studied. For example if a compact a/c is preferred the definitive aircraft can be visualized as a Grumman Intruder A6E front fuselage married to a Boeing XF 32 Fighter suitably scaled up to accommodate a provisionally B 52 size weapons bay. Not much prospects of a pretty aircraft but it is a compact aircraft. Like the great all round-ers of the past e.g. Mosquito, JU 88, Pe 2 -not quite as small as a fighter and not quite as large as a conventional bomber.

The Boeing XF 32 , despite

ribald commentary, is stealth wise extremely interesting and well thought out,

and in spite of its boxy looks, was like the Lightning, a nimble performer that

also conformed to area rule. The accompanying sketch which is provisional, uses the concepts developed for the Boeing XF 32, combines it with concepts for the YAK 141 and shows a possible compact intruder configuration.

The stages of the

programme

To

rush in directly and work lazily ensure and

guarantee getting stuck later. The first step is to fix that the course being

plotted is the best of all the many options.

The second is to develop a “true” (and not “Administrative” or "naam ka waaste" ( "for the sake of a name" tr. hindustani) TD. A well planned technology Demonstrator can significantly

reduce development costs, time and effort because much of the hardware

development proceeds in parallel.

1. Solution

search

There are four basic types of layout that can be considered for the Betal AMCA. These are Conventional i.e. with tail, canard, Lippisch type tail less and Horten type flying wing. These need to be evaluated for engineering and strategic factors.

Development factors will mean evaluation for technical challenges or essentials- e.g. degree of stealth, aerodynamic risks, reliance on FBW/artificial stability etc.

Strategic factors may mean the ability to change the engine source or vendor or accessories from one to another –on the assembly line. Ease of production, maintainability, and many of the more important matters can be pooled and a mutually acceptable list for evaluation is to be prepared.

The

table 2 gives a format to illustrate the principle .I have put in my “gut feel”

figures but with commercially available off the shelf aggregates, computers, current software, free flight and R/c models, customer inputs, superstitions

and “old wives tales” can give good working estimates for many of the factors.

Table 2 Indicative decision matrix with arbitrary values; without weightages.

|

|

Configuration |

Stealth Signature |

Range |

Field perf. |

Weapons storage |

Upgradability |

FBW dependence |

Totals |

|

1 |

Horten |

10 |

10 |

07 |

06 |

05 |

05 |

43 |

|

2 |

Lippisch |

08 |

09 |

08 |

06 |

06 |

06 |

43 |

|

3 |

Canard |

06 |

06 |

10 |

10 |

07 |

07 |

46 |

|

4 |

Conventional |

07 |

07 |

09 |

09 |

10 |

08 |

50 |

The Tabulation

allows many people including the customer to participate in the process and to

see what has been already brought to the table and so spark brain storming.

Properly documented it avoids hesitations later with “Should we have tried

that?” kind of questions which can cause wastage of time. At the same time one

should not get into analysis paralysis and the process should be truncated

within a few months for this is an aid and not an end in itself. The next step

is to build a Technology Demonstrator.

The HP 115 Technology Demonstrators

A

technology Demonstrator is an “experimental” certificate category aircraft that

is cobbled together and is meant to fly for a few hundred hours at most. To

speed up its design and construction it is often made up from various

aggregates of other “in production” aircraft and no test are wasted in areas

that are not required to be explored.

The

Handley Page 115 technology demonstrator is a good example of its breed and its

utility. Its story which I feel is important in our context is something like

this: In the process of studying the problems of commercial supersonic flight

it was felt that the understanding of the low speed handling and the capability

of generating “vortex” lift was an important part in finalizing of the

Concorde’s design and needed to be verified and optimised.

Initially

a glider towed by a Canberra was proposed until someone calculated the fuel

bill and the Canberra’s operating costs and suggested that a self- launching /

self- propelled would be cheaper! The resulting HP 115 was a small single seat aircraft powered by an early mark

of the Bristol Siddeley Viper of 8.45kN ( 1845 lb.s.t) and a max speed of 400

km.p.h which was limited by air frame stress rather than engine power and an

endurance of 40 mins. With an empty weight of 1668 kilos and a MTO of 2300

kilos and it proved to be an extremely pleasant to fly aircraft and was flown

well beyond its design limits by its delighted pilots. It was a small aircraft

with a span of 6.1 mts, a length of 13.72 and a wing area of 39.98 sq. mts. In

comparison and as an illustration of the TD concept, the Concorde’s

corresponding figures were Span 25/ Length 61/Wing area 252 sq.mts. and an empty weight of 78 tons and a MTO

of 185 tons.

To speed

up the programme the airframe and systems were very logical and minimum. There

was no electrical generation, the GSI being operated off a battery and the

flaps and air brakes were operated, as with the HF 24 glider, by a pneumatic

systems operating off a compressed air bottle. The structure was a central

light alloy girder with the cockpit “egg” in the front and the ASV Viper at the

back fed by a simple S intake- a nice stealth feature I am sure no one then

thought about in 1961. The Nose undercarriage was from a Jet Provost and the

non- retracting (because of the expected low speed) main U/c was from a piston Provost.

The Delta wings leading edge was of wood so that its profile could be modified in situ. if required. I find it amusing that a TD for a large M

2.2 SST was a frail and tiny aircraft with wooden parts and a fixed u/c from a

basic trainer. In one of my blogs I reproduced my notes on copying in creating an Engineering design. You will notice looking at the HP 115 that by putting in a "bomb bay" behind the cockpit pod you have the beginnings of a TD for a natural stealth intruder.

Computers, TDs & caution

Those

who believe that computers have replaced wind tunnels & practical TDs are

no longer required will be paused, one hopes, by the recent experience of

Mercedes in F1 racing design. Mercedes has forgotten more about racing design

than I will ever learn but in the replacement of “Wing spoilers”- which have a nasty of coming off and causing the car to waver- with what I

call in “body negative lift” rule they

apparently came to grief. They recently said they followed all the data and

took all the correct decisions but they got the wrong solution because the

aerodynamic “press down” (my term) was not stable- something that happens in

natural flows but a computer will not dream of it because that idiot lives in an realm where all flows are rock steady

unless defined. It will be noted that Mercedes being Mercedes, they find no

embarrassment in admitting that there is failure and there was fault. I have seen Reluctance

to admit goofs may cause more delays to a project than correcting the goof

itself.

The Betaal Technology

Demonstrator

Purpose: Firstly to demonstrate that a subsonic

5th.generation intruder is a tactically feasible solution- by flying such

sorties in realistic practice.

The

second objective is to prove that due to internal carriage of weapons the subsonic aircraft

will perform better & be more effective in the tactical attack role than a

higher performance a/c e.g. the SU 30 MKI with external Brahmos and higher

signatures.

Third

objective is to develop confirmed data of all aspects of stealth a/c design,

production, maintenance operation and development of optimum tactics for such

aircraft.

The

Fourth objective is to cut down development time, cost and uncertainty of the

Betaal project by making “parallel development” possible e.g. test flying the

concept e.g. attack sorties in the stealth mode on the TD whilst the actual

prototype is under build.

Description of the TD

Side by

side seating high subsonic intruder optimized for internal carriage of AI

weapons. Three jet engines whose operation will be computer controlled for

minimized fuel consumption.

Fuselage

Light

alloy box girder forming main structure with the internal volume forming the

main weapons bay. The cockpit egg is in the front and the rear of the girder

carries the S duct of the main engine and all the flight and landing loads- as

in the Gnat. The fuselage is skinned by unstressed RAM Carbon- foam, -carbon detachable

skin for ease of modification to improve RCS and very large areas are

detachable for ease of access and for up gradability.

Wings

Various

configurations are under study. The ones shown is a provisional sketch that has

shown promise on the computer. It compromises of a tailless swept wing with a

LE sweep of 350 on the inboard panel and 400 on the

outboard. The inboard section is a 633- 410 aerofoil and the

outboard section is the same but on a reflex camber line. A thicker section

showed good handling at low speeds. The wing is of metal construction in the first

prototypes to settle quickly and at low costs the performance predictions and

on gaining confidence will switch to Composites. As with the HP 115 parts of the

wing that is identified for “tweaking” is in wood to quickly implement in situ design

changes and resume flight tests. The other sketch- of the full size Betal

shows a “winglet”-ed Delta rather like the XF 32 but with "buried in teh wing" boost engines ,if required.

Systems All systems will be adapted from

the chosen type of Biz-jet to save development time and cost. Electrical,

Navigation and general Avionics, cockpit displays, fuel and propulsion systems,

hydraulics, electrical, ECS will be all adaptions as far as possible down to

piping, wire harness clamps et al. This will reduce the development task to

just about the airframe.

Special Systems

Propulsion A jet engine at part throttle is

also remarkably inefficient fuel consumption wise. An attempt will be made to

use a cruise engine – operating at its optimum economy condition- for the main

flight and one or more boost engine for MTO and dash. This idea was serious

enough for the De Havilland to use it on the Trident on the Mediterranean

operations. Because these boost engines were used for short duration they had

T/W ratios approaching 10:1 in the 1960s. The reason a simpler A/B solution is

not used because the A/B system continuously creates a thrust loss of about 1-2

% in cruise and has a high IR signature when boosting i.e when in presence of

the enemy.

Stealth The use of an un-stressed outer

Carbon/Foam/carbon skin will permit the use of rapid experimentation of the

stealth features. It is proposed to use both Ufemitsev and Hopeless Diamond

Techniques are proposed to be explored for serviceability and effectiveness.

The use of inlet mesh grids to reduce signature and their effect on performance

especially in icing will be examined.

Data Processing The penalties of side by side

seating have been accepted in some of the project studies so that

intercommunication between crew –the last link in the data chain-is

instantaneous. A 5th generation aircraft must have enormous data

processing power and it is feared standard engine gear boxes will not be able

to handle the power requirement of computers, displays, attack radars and all

such systems that are needed or will be in the future. The feasibility of

generating such power separately of the propulsion engine and controlling the

generation as per sortie requirement will be explored.

Durchstromteflugel The

Swiss had in the 1950s worked on the

“through flow wing”. They got interesting results achieving STOL take off runs

of 300-400 mts. It seems to be some form of flap blowing. This concept needs a

re- look because whilst the Betaal is too big for carrier operation the

Technology Demonstrator is just the right size for a carrier borne stealth

strike aircraft, It can be easily re- engineerd for full scale carrier

operations and its dimensions have been fixed so that it can be – if required –

tested from non CATOBAR operations. CATOBAR will of course be no problem and indeed the aircraft can be made

somewhat smaller,

Development An aircraft should be cleared for

development if it can be readied for initial production within ten years. The

project monitoring for this time target begins from day 1 and if indicated

project times are not maintained the project should be closed down or put under

new management as after 10 yrs delay in a marker event the project will become

obsolete.. A aircraft that is not cleared for production in ten years from go

ahead is a resources sink. Delays ensure that progress is ensnared in

revisions. If the team is not up to the mark –which is why the initial delay

happens- subsequent corrections swamp their capabilities. The project spins out

of control.

The use

of a well thought out technology demonstrator helps by allowing a big part of

the testing to be done parallel to the main project. The second benefits is

that corrections on the prototype are reduced.

Table 3

The

indicative time scales for both teh TD and the final aircrafy are:

|

No |

Time

Sl. (Months) |

Phase |

|

1 |

0-12 |

Project studies,

evaluation of results |

|

2 |

6-24 |

Evaluation with

customers, refining of concepts, vendor base development ,selection of final

configuration |

|

3 |

24-60 |

Start of drawing release, start of

manufacture of prototype |

|

4 |

60-96 |

Flight trials of

technology Demonstrators, start of Drawing release of Betaal Prototype |

|

5 |

96-120 |

Roll out and

start of flight trials of the Betaal prototypes. |

|

6 |

120-144 |

Release for

production. |

These time scales are based on current average Industry standards. Indeed some have been achieved or exceeded in India.

Cost

Our development costs need serious audit. By my estimate the Tejas programme has cost 30% more to IOC 1 than the entire F 16 programme when it should have cost only about one third or one fourth as much. DPSU/ Science Project laboratories costing in India appears to be dependent on “how much one can ask and get away with”. This is not facetious. Indeed I have heard in the 1990’s the acolytes of one famous “Scientists” in awe of their “Guru’s ability to get a crore’s worth of project funding sanctioned on a project proposal written on ONE A4 size sheet. It was not an admiration of his erudition but awe of how much clout he had in the system- and therefore how much benefit he could perhaps pass on to them. The conversation- in tones of weighty respect – I have heard.

What I believe is that there is much room for improvement- perhaps by a factor of 5 times at least. Below are the project costs of several representative American projects. The estimation of project cost must factor in different time periods and types of aircraft, Present day value, currencies exchange rates and Purchasing Power parity are all to be considered. I have therefore converted funds to the amount of gold equivalent that could have been purchased by the sanctioned fund at the time of sanction. When re-finance was repeated due to failure to maintain targets these were summed up as total amount of gold equivalent that was spent on the project. This then I have converted into Indian Rupees going by the present price of Gold. The results are given in the table 4.

Table 4 A Representation of Project costs US and Indian.

|

Sl.

No |

Type |

Year |

Dev.

Fundx $ millions

|

US

Gold /Troy oz |

Project

Cost in terms of 10

gms of Gold* |

Project

cost. in INR Crores ( 1 crore=10M) ** |

Relative

cost/F 16 A as 100% |

|

1 |

B 52 |

1952 |

100 |

$ 38.52 |

80,73,727.9 |

48,846 |

46% |

|

2 |

Marut HF24 |

1956 |

Rs. 16 crs |

|

|

2240 |

|

|

3 |

Lockheed S3

Viking |

1969 |

491 |

$ 41 |

349,68,536.5 |

2,11.664.5 |

207% |

|

4 |

XST

|

1976 |

10.4 |

$ 133.7 |

2,40,956 |

1457 |

1.37% |

|

5 |

F 117 |

1978 |

340 |

$ 208 |

50,83,653.8 |

30,771 |

30 % |

|

6 |

ADA Tejas |

1983 |

INR 55,428

Crores.*** |

|

275,21,000.0 |

1.37.881 |

132.1

% as of FOC1 |

|

7 |

LM F 16 |

1969 |

$891 |

133.7 |

208,19,000.0 |

1,04,391 |

100 |

Notes: *

In large parts of India the traditional weight unit of gold is the Tola which

is approximately 11 gms. The 10 gms unit is perhaps the current “decimal”

equivalent.

1.

**The

comparison of project costs to a standard base is computed on the price of Gold

in India as of 28/03/23.

2.

***

This is for the development of the airframe as of & up to a “FOC 1” where

the a/c could be accepted with 83 “concessions”; The inability to fire its 23

mm gun armament is illustrative of the nature of

some of the concessions.

3.

In

comparing cost figures between Indian & American projects it has to be kept

in mind that the average American

Aerospace Engineer as of 2022 is paid $ 98,769 per annum as per official US

sources. The average Indian Aerospace engineer in DPSUs and Government Agencies

perhaps gets one fifth of that amount.

4.

The

F 16 programme to service entry of the A model

cost Rs.1,04,391 crores or about 32% less than the Tejas programme to

IOC 1 where the aircraft was put into “service” with 89 concessions and without

a gun. An analytical investigation into where the expenditure occurred will be a

very necessary correction or else a few inefficiently- run projects can suck away funding from more

deserving projects.

Conclusions

There is

scant evidence to believe that our development costs are lower than those

abroad. In fact quite the reverse is indicated. This is good news because it

shows that with reorganization our Defence development budgets can stretch much

further. The same applies to project times.

A

subsonic 5th generation combat aircraft is a feasible concept and

its development will not cost a great deal of money. Professionally managed it

can be ready for service in ten years and at a total cost of 8000 crores i.e. about

2000 crores for the Technology Demonstrator and about 6000 crores for the

Betaal Intruder.

2.

The

average American Aerospace Engineer

is paid $ 98,769 per annum as of official US sources 2023. The average Indian

Aerospace engineer perhaps gets one fifth of that amount.

3.

The

figures indicate that the project finances being asked for are extremely

wasteful or are grossly inflated to create a

resources crunch so that alternative developments cannot be funded.

Conclusions

A

subsonic 5th generation combat aircraft is a feasible concept and

its development will not cost a great deal of money. Professionally managed it

can be ready for service in ten years and at a fraction of the cost of ADA

programmes.

Foot notes

Comments

Post a Comment